HOW YOUR FURNITURE IS MADE

Every product we design aims to make your life better.Old Growth Timber

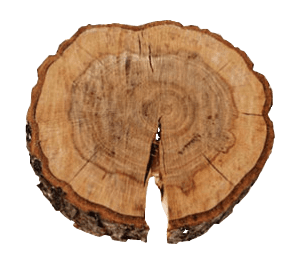

Every piece of our furniture tells a story. The story doesn’t start in our shop, but rather hundreds of years ago in a vast virgin forest, when the first European settlers were landing on our continental shores. The saplings born in this era eventually grew to monumental heights, and provided a stock of lumber to the westward expansion. We refer to these original American woodlands as “Old Growth” forests.

Of the generations of trees that followed, only the Old Growth forests can lay claim to being the eldest and most grand of them all. It is these mighty timbers that the pioneers felled to create the structures that secured their well-being. No longer available, the only sources for Old Growth Timber would be to reclaim it from our ancestors. The modest hand tools and construction techniques employed at the time created a signature that defines this fleeting resource.

Barn Reclamation

Drive through the heartland of America, and you will pass hundreds, if not thousands, of old run-down wooden barns, railcars, mail-order homes and historical buildings that sit idle after generations of use. Exposure to the elements has slowly eroded their original form. An eyesore to some, and a hindrance to others, we see these structures as a diminishing resource that we attempt to reclaim before they are dozed, burned or disintegrate.

We seek out buildings that are testaments to the traditional construction processes used by our ancestors, seasoned through lifetimes of natural weathering and hardship that only mother nature herself can provide. The barns and houses that we reclaim are meticulously disassembled, in order to preserve the character and history that follows each board. We take pride in knowing that our primary construction material is as old as our country herself, and a living tribute to our heritage. Once we have a building dismantled and the wood delivered to our shop, we grade each board to obtain only the soundest of boards suitable for our furniture. Our boards are handpicked to ensure that they are dry, stable, and free of structural issues caused by high levels of moisture.

Sorting and Grading

It is the first step once a building is dismantled and the wood delivered to our shop. We thoroughly inspect and grade each board to obtain only the soundest of boards suitable for our furniture. If the board does not pass our inspection, it does not make the cut. After we have separated out the lumber that does not meet our stringent standards, the highest quality boards are separated into over a dozen different categories, based on weathering, grain, color, size, character marks, and structural potential. Our designs and patterns require a specific and rather lengthy selection process, in order to provide the tones, structural integrity, contrasts and character only found in Western Heritage’s products.

Preparing reclaimed barn wood for use as fine-furniture material is more of an art than a process. Each piece of reclaimed wood is very unique with its own characteristics: nail holes, notches, cracks, stains, ax marks, old brands and the occasional “I love Jenny,” are all elements to be preserved. These character marks, along with the intrinsic coloration, patterns and grains present in the reclaimed wood determine the classification each board as it enters our shop. These various classifications are critical to our designs. Each piece is distinct in its history, beauty, and was harvested, most likely by hand, by the original craftsman 100-200 years ago.

Wood Selection

It is the most critical step in creating the beautiful patterns and mosaics found in our furniture. A detail only seen in Western Heritage Furniture’s products, is the elegant arrangement of contrasting colors and character in our reclaimed woods. The rainbow of colors along with the tell-tale saw marks and nail holes present in our furniture are anything but random. Our designs require specific placements of the various categories of reclaimed wood, with the personality of each piece born in the wood selection process.

We determine the coloration and textures of our final product not through staining or distressing, but specifically through our experience and knowledge of selecting barn wood. In larger production shops, classifications are non-existent, and these meticulous steps are ignored, evident by the flat mono-tone appearance of their creations.

Bench Made

furniture is made by a single craftsman, quite literally, on his workbench. Most furniture out there, especially “value” furniture, is made in a production line. Each worker is responsible for a single aspect of the creation of each piece, before moving it down the assembly line to the next worker. There is nothing wrong with this type of furniture construction; there is, however, something uniquely gratifying about Bench Made furniture.

In our workshop, all of our pieces are hand-made, top to bottom, by a single craftsman. This takes a little longer, but each piece is “owned” by the artist making it. He takes the time to make sure every edge is sanded properly, the mortise and tenon joinery is solid, the drawers and doors work like a dream, and the final touches are added. More care and attention is put into the whole piece, rather than on a line where he would be unaware of the goals of the final product.

Sanding

Reclaimed wood is unpredictable. The beauty found in each product is based on our ability to maximize the amount of character marks left by the original craftsmen and the weathering provided by mother nature. The challenge aspect of this task is assuring that each piece is also smooth to the touch and well protected. We accomplish this through our rigorous finishing process not found in any other reclaimed wood shop.

Our small team of expert finishers treat each piece like it’s their own, carefully chiseling, sanding, inspecting and re-inspecting every saw mark, nail hole, groove and crack that we strive to expose. We take pride in the fact that this is the most lengthy part of our entire construction process. To speed this process up would be a disservice to the wood, our art, and to the generations of souls who will enjoy our masterpieces.

Our Finish

One must touch and feel our furniture to fully appreciate the care we take in our finishing process, and the words velvety, smooth and soft definitely come to mind. To create this unique feel and protect our furniture for generations of use, we have adopted a process that sees several iterations of sanding and lacquering before the final waxing. The hand-waxing may be the most back-breaking step in our entire process, but is critical in protecting the furniture and creating a smooth, lustrous finish that highlights all the colors and textures present in the reclaimed wood.

The hues and patinas that radiate from our furniture are dictated by the wood we hand-select combined with our unique finishing process. Often imitated, but never replicated, we implore you to compare our artwork with other shops. You will know which ones were created with love, one at a time and hand-crafted with an unprecedented attention to detail in our small shop in Jerome, Arizona. We expect nothing less in our furniture, and neither should you.

Inspection

Our standards for quality are unmatched in our industry. Never resorting to high volume production practices, we make every piece of our exquisite reclaimed wood furniture to order. In this effort to craft heirloom quality furniture, it is our duty to make sure each piece adheres to the excellence one would expect given our experience, craftsmanship and care. Each piece is inspected, signed and delicately wrapped before it makes it’s way to your home.

Our Delivery Services

In-home delivery has always been a big part of our company, because we believe customer service is just as important as the quality if the furniture. We treat each piece of furniture we craft with love and respect, and we want this additional care to continue all the way to your home. We offer white-glove delivery, assuring you that someone from our family will usher your new work of art all the way to its destination. After each piece is thoroughly inspected, it is carefully blanket wrapped and covered to protect it on it’s journey. We’ll meet you in person, answer any questions, explain each detail of the piece and let you know how to further care for your furniture. If you’d like, we’ll set it up anywhere you need.

As you take possession of the furniture piece a new life is started. What you now own is a one-of-a-kind artisan piece of reclaimed barn wood furniture that has been specifically tailored for you.

“John the delivery person was right on time and very polite. He also helped me carry it into the house which was a nice gesture. I want to thank you for you exemplary customer service and care to details. I work in sales and deal with a lot of people and companies on a day to day basis and it is rare to see this type of service.” – Cathy